Our Services

Powder Coating

Powder coating is a dry finish process that involves the use of finely ground particles of pigment and resin. The pigment is the actual coloring and resin is a glue that bonds the color particles. The part to be coated is suspended from a negatively charged hook that grounds the part. A special nozzle is charged with a high-voltage, low-amperage electrostatic current. The spray gun shoots an air/powder mixture, and when applied to the part, creates a lock between the part and the paint particles. The parts are then placed in a large baking oven when cured with heat, the powder particles fuse together to create a single coat finish that cannot be achieved by any other method of coating. The resulting finish provides a wide range of performance properties, offering excellent resistance to corrosion, heat, impact, abrasion, fading from sunlight, and extreme weather. The molecules of the powder actually interlock providing a strong flexible film that is far superior to liquid paint

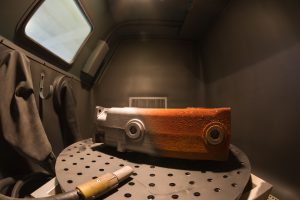

Sand Blasting

Abrasive blasting is valuable as an efficient, high-quality method of surface penetration. Blasting is also used for other purposes beyond surface preparation, such as removing microscopic machining burrs from engine parts, etching glass, carving of names and designs in wood and stone or surface hardening of manufactured parts.

Paint/Coating Removal/Repairs

Shortly after the invention of coatings, came the realization that coatings need removal. No Coats Technologies is a new way of doing an old process; that of removing coatings.

Our proven unique green process can reduce operations cost, and improve productivity across a range of industries.

With fast turnaround times, you will get your finished product quickly. We also offer pickup and delivery on some orders.